PDXpert PLM Software

PLM Good Practice

Identifying alternative (ALT) parts for your bill of materials

Each item in PDXpert PLM software has a Source list, which may contain any number of approved supplier items that can be sourced for that item. Each approved item can be ranked relative to its peers and include its own rich data, including part number, data record revision, cost, and datasheet file attachments.

This application note describes how to take full advantage of PDXpert software's Sources list to identify parts qualified for all uses, as well for limited use in a specific bill of materials.

An alternate part is a useful, if sometimes expensive, tool for fixing a supply-chain crisis. Application-specific interchangeability always requires extra effort. Alternate subassemblies add complexity to build instructions, inventory, routing, inspection, calibration, field support, and repair. After the crisis has passed, consider replacing the alternate list with your preferred part.

Definitions§

There are several distinct ideas related to alternate / interchangeable / replacement / substitute / superseding / variant (variation) terms. Feel free to substitute your industry's terms for these concepts:

-

Superseding parts are

-

Interchangeable, and revised (part 1234 Rev 1 revised to Rev 2). A part's previous iteration (revision and/or lifecycle) is always replaced as a new iteration is released, without affecting higher-level part numbers or iterations.

-

Non-interchangeable, and replaced (part 1234 Rev 2 is removed from use, and part 2345 Rev 1 is used in its place). This requires human judgment to decide if changing the part requires a new number, and then if the part's parent(s) must be revised or be assigned new part number(s) if they're not interchangeable.

-

-

Variant parts have similar function or purpose, or are derived from a common design, but are not interchangeable, and require distinct part numbers. These may share most – but not all – items on a BOM, or share fabrication specifications that may vary in dimension or material. After these variants are released, each has its own history; technical content, lifecycle, or interchangeability often diverges from the common starting point.

For example, you may create a product for North America, but have a variant for Europe that requires a different power supply. You'd likely first construct one complete variant, then copy that to a new part number for the other variant. This second variant must be edited to use the correct power supply. Over time, the power supplies and their parent assemblies may evolve other differences, such as regional performance, user documentation or certifications.

-

Purchased manufacturer source parts are fully interchangeable manufacturer parts that are qualified to meet internal requirements, and then purchased for use without alteration. An internal (home) part number lists these manufacturer source parts, which are freely intermixed in one inventory location. For example, a standard 100-ohm resistor is qualified from various manufacturers (partners). These manufacturer parts must be interchangeable for all applications because they'll be intermixed in the same inventory location. Your internal part (the requirement) has a Sources list that shows the set of qualified manufacturer source parts.

-

Alternate parts are not interchangeable for all applications, but may be used interchangeably for a specific application. For example, a 100-ohm resistor is not interchangeable in most cases with a 120-ohm resistor; they must have different part numbers. However, there may come a day when the preferred 100-ohm resistor is simply unavailable, and Engineering agrees that the 120-ohm – while not preferred – is acceptable for this particular use. They're also considered "phantom parts" because you typically don't maintain a distinct inventory location, but simply refer to other parts.

Basics of supplier source identification§

Purchased parts often represent the bulk of a unique product's components. Screws, resistors, paint, and other off-the-shelf items are acquired to fulfill standard functions. Often these parts are available at little cost from several different mass producers, any one of which would be equally suitable for supplying a useful product.

By definition, every purchased part in your warehouse should have at least one, and preferably several, approved supplier parts. Multiple supplier parts are interchangeable with each other when their relevant functional and physical properties are equivalent. Part interchangeability – that is: form, fit, or function equivalence – implies that any approved source can be used for the application. (For a complete discussion, see Applying principles of interchangeability to your bill of materials.)

Some approved parts may have attributes that are irrelevant when placed into your intended application. Occasionally, those irrelevant properties will actually increase the cost of the item, such as when a 100Ω, 0.1% tolerance resistor is used in place of 100Ω, 2% resistor. In this case, you may want to assign a source rank that indicates to your Purchasing team how you judge the relative merits of the interchangeable sources.

After you've identified your purchased part's sources and validated that their specifications meet your purchased part's requirements, they're approved on an engineering change form and can be used in production.

Application-specific alternative parts§

The interchangeability of sources considers how the item is used in a specific application. In general, it's best to consider the specific application as broadly as possible for all expected uses: you don't want to have to carefully examine the original requirements for a 10µF 10WVDC aluminum electrolytic capacitor each time it's applied to a new design.

However, in some cases, a specific application can accept a part that would not be equivalent in all possible situations. For example, a specific assembly may be able to accept a 12mm screw length even when an 8mm screw is preferred. Clearly, a 12mm screw is not completely interchangeable in all applications with an 8mm screw, but it may be fine where the extra length does no harm. Moreover, if the production line is stopped, it may be essential to provide a workable substitute for a preferred item. This substitute is commonly called an alternative ("ALT") part.

The set of ALT parts for a particular application are identified using your own (home) part numbers, not the manufacturers' (partners') part numbers.

Problems with traditional attempts to identify ALT parts§

An ALT part has always been a specific solution applied to a specific bill of materials. Intuitively, most design engineers believe that the easiest representation of the part alternatives would be to simply add them to the place they're needed, on the affected BOM.

The goal is great. However, the reality is that adding an ALT to the bill of materials is often meaningless, and perhaps even risky.

Consider how the manufacturing system works: parts listed on the BOM get translated into a demand based on their quantity, which is then multiplied by the number of assemblies to be produced. How does the MRP system translate an alternative part, possibly listed on the BOM with quantity of 0 or a unit of measure ALT or A/R, into a purchase quantity? In most cases, it doesn't. What happens if the quantity and units are useful (like 7 cm) or the ALT unit is converted to each? Possibly both the preferred and ALT will get purchased for the same purpose, with unhappy effects on your inventory.

The manufacturing team may have a standard method for dealing with these problems. They may simply filter out all of Engineering's alternative parts, or accept them at zero quantity. Neither of these is likely to support actual buying activity, so Purchasing may also get the engineering BOM with the hope that it'll be remembered months or years in the future. More likely, Engineering will get a request for help, or production will simply be delayed waiting for the preferred part. Engineering's efforts are, at best, occasionally used but often wasted.

BOM-specific alternative is a phantom part§

Returning to first principles, we know that a part number is assigned for each unique part. If the application of a part is new, then a new part number should be created.

An alternative ("phantom", or non-inventoried) part is simply a unique list of home parts that are approved for a specific application. Creating this phantom — a distinct part number and application-specific list of approved sources — solves the problem of transferring the engineering list into the manufacturing system.

Each of the alternative sources must result in a higher-level assembly that is fully interchangeable with assemblies that use any of the other alternate sources.

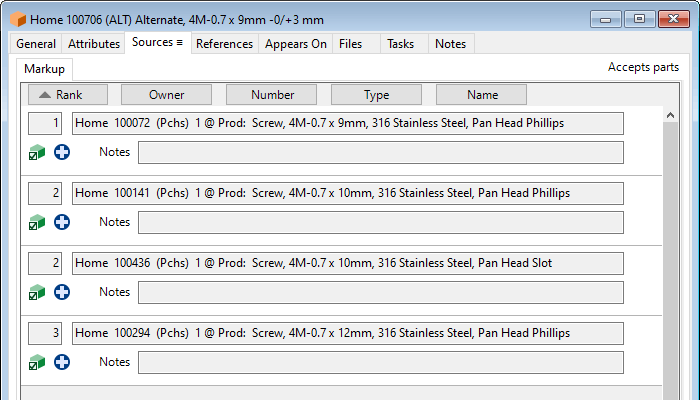

The ALT part's description provides some guidance on how (and possibly where) it's used. On the part's Sources list, the preferred part is always ranked as 1, and non-preferred alternate parts are ranked as 2. A more detailed preference ranking can also be applied; for example, a 4M-0.7 x 9mm Phillips head is preferred; 4M-0.7 x 10mm Phillips and slotted head are ranked as 2; and 4M-0.7 x 12mm Phillips is ranked third. Some MRPs can model only Primary/Alternate choices, and not more specific ranking.

A phantom part can be naturally represented on the PLM BOM, and at the MRP alternate BOM location. It typically won't be inventoried under its own number, but simply "sourced" from other inventory locations.

These alternate source parts can also be subassemblies or kits, such as LED + resistor pairs.

Defining and exporting your ALT parts§

Assume that your internal part numbers 1001 and 1002 are both interchangeable on a specific assembly, but not for all purposes.

Uniquely identify ALT parts by creating a new Part Types member like Alternate. Then, for the unique application:

- Create the new Alternate part with a normal part number 1003, or use a unique part number prefix like ALT-1003. Use a description that makes the ALT part easy to find, and shows its use and constraints.

- Add standard parts 1001 and 1002 to the ALT part's Sources list.

This is similar to how you define a Purchase part, because both Purchase and Alternate parts show your organization as the part Owner, and have a Sources list with some parts ranked as equivalent, and some not. The important difference is that:

-

The Purchase part's Sources list shows other (partner) organizations' parts that have been qualified as interchangeable for all applications.

-

The Alternate part's Sources list shows only your own (home) organization's parts that have been qualified as interchangeable for a particular application, and are not otherwise interchangeable.

It's essential to know how the downstream manufacturing system wants to import this arrangement. PDXpert's standard BOM with Sources report will show the ALT part on the BOM with its source parts, and there are various data transforms to export this relationship. However, your MES/MRP may require a different treatment. For example, some systems import only a primary part, and the alternate(s) must be loaded manually; other systems use a column for each option (PRIMARY / ALTERNATE) and the export transform must elevate the phantom's Sources into BOM rows. Your production system also determines how (or if) you represent "kits" of alternate parts – for example, replacing one kit (LED123 and its 100-ohm resistor) with another kit (LED456 and its 120-ohm resistor).

It may take a bit of analysis – and probably some discussion with your manufacturing staff and IT team – to determine the complete solution based on your inventory management practices and MES/MRP capabilities.

Contact us if you'd like to discuss how the general concepts in this note may be applied to your situation. We'd be happy to address other PLM software good practices — ask us!